Real-Time Vehicle & Trip Management for High-Volume Operations

How SAZS Apps ERP eliminated ghost trips and transformed logistics operations with GPS-integrated tracking and weighbridge validation across crusher, quarry, RMC, and brick plant sites.

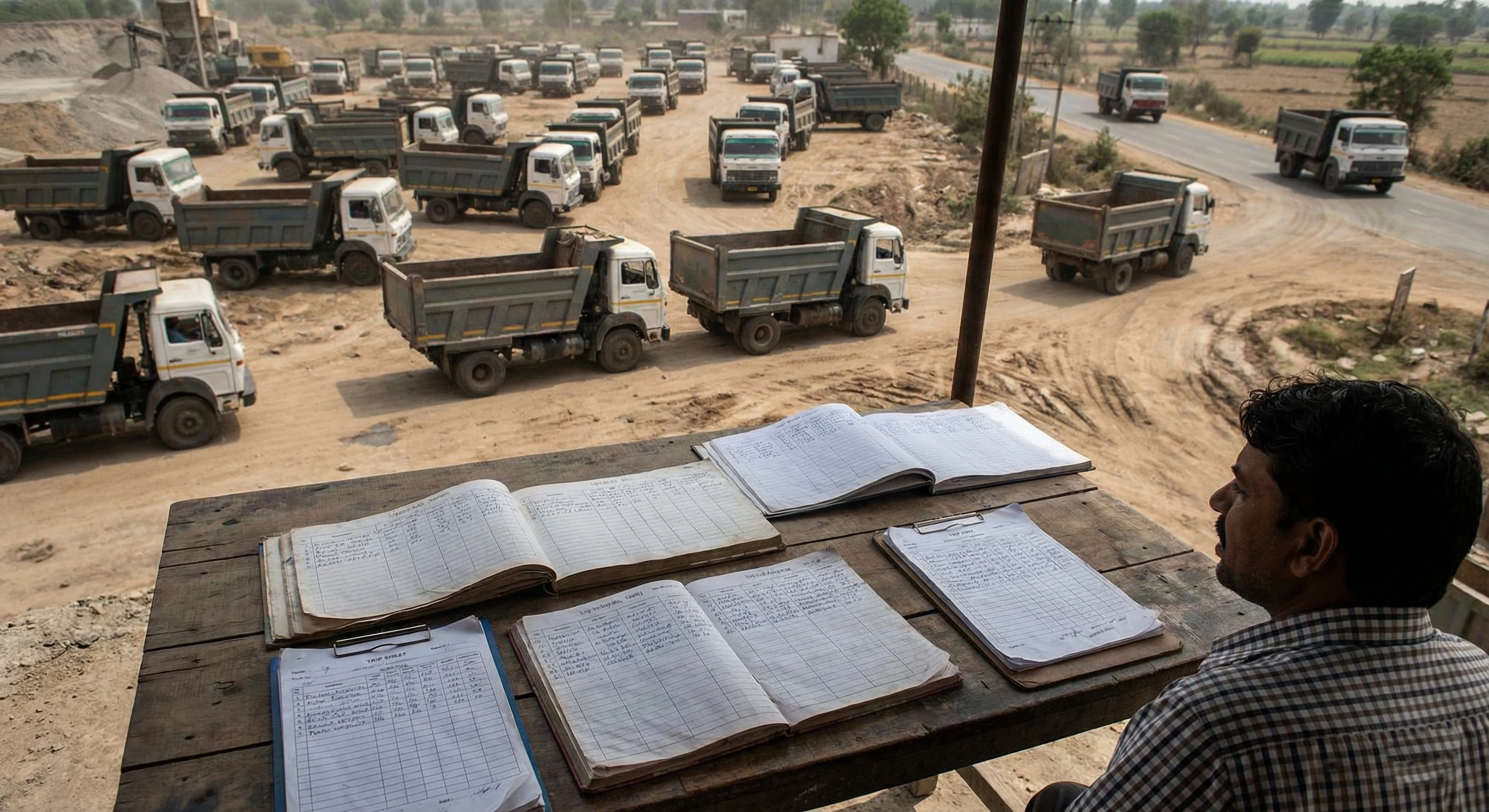

Logistic Blind Spots and "Ghost Trips"

For businesses operating across multiple Crusher, Quarry, RMC, and Brick Plant sites, transport is often the largest unmanaged cost. This client faced severe logistical challenges:

Critical Pain Points:

- Fake Trips: Drivers or contractors claiming "ghost trips" that never occurred.

- Duplicate Entries: Manual trip logs leading to double-billing and accounting confusion.

- Low Asset Utilization: No data on which vehicles were idle or which drivers were underperforming.

- Billing Disputes: Constant friction with transport contractors over inaccurate trip counts.

"Without visibility into actual vehicle movements and trip validation, logistics costs can spiral out of control—costing businesses millions annually."

GPS-Integrated Logistics & Weighbridge Validation

SAZS Apps ERP implemented a rigorous Trip Management System that turned logistical guesswork into a precise science:

GPS-Based Tracking

Real-time movement monitoring of every vehicle across all sites.

The "Double-Check" System

Every trip is automatically validated against weighbridge data; if no weight was recorded, the trip isn't counted.

Automated Billing

The ERP generates transport invoices based on verified trips and actual tonnage, eliminating manual errors and malpractice.

Performance Dashboards

Detailed reports on driver behavior and vehicle-wise productivity.

Streamlined Logistics & Verified Billing

The GPS-integrated logistics system transformed the client's ability to manage their fleet:

"The transformation was remarkable. We eliminated ghost trips entirely, reduced billing disputes to zero, and our transport contractors actually thank us for the transparency. Our logistics operation went from a cost center to a competitive advantage." — Operations Director

Key Technologies & Integration

The GPS-integrated logistics system seamlessly connects with existing operations:

- Real-time GPS tracking on all vehicles across Crusher, Quarry, RMC, and Brick Plant sites

- Weighbridge integration for automatic trip validation and tonnage recording

- Automated billing workflows that eliminate manual entry and human error

- Mobile dashboards for managers to monitor fleet performance in real-time

- Driver performance analytics for identifying top performers and training opportunities

Why This Matters for Construction Material Operations

For high-volume operations running Crushers, Quarries, RMC plants, and Brick manufacturing facilities, logistics visibility isn't optional—it's essential for profitability. The combination of GPS tracking and weighbridge validation creates an ironclad verification system that:

- Eliminates revenue leakage from ghost trips and billing errors

- Improves contractor relationships through transparent, timely payments

- Maximizes vehicle utilization and reduces idle time

- Provides data-driven insights for fleet expansion and route optimization

The result? Logistics transforms from an unmanaged cost center into a source of competitive advantage and operational excellence.