Transforming Customer Experience & Order Speed in Heavy Building Materials

How one crusher, quarry, RMC, and brick plant operation moved from siloed spreadsheets and slow dispatches to a unified, high-speed customer lifecycle with SAZS Apps ERP.

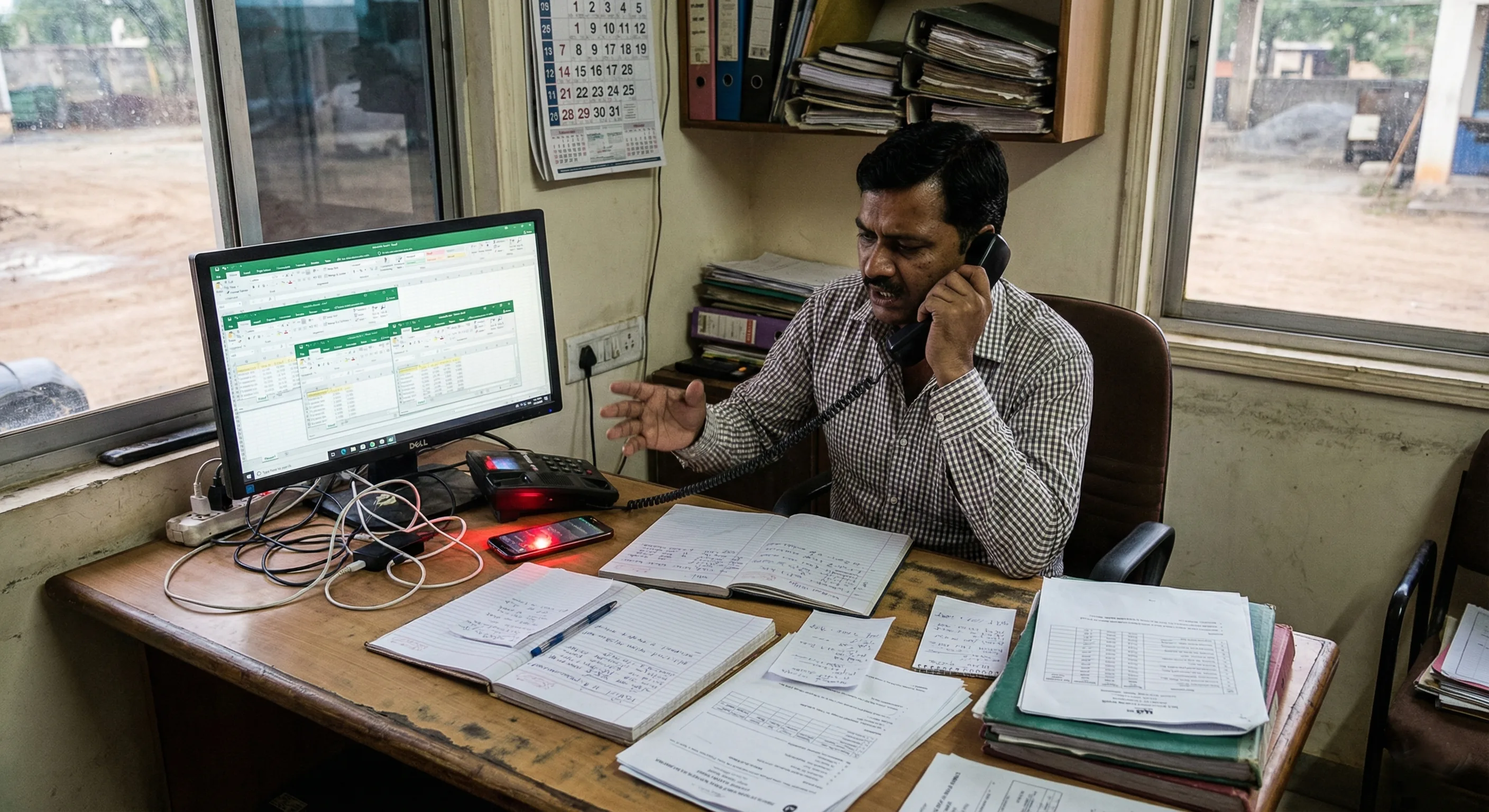

Siloed data, slow deliveries, unhappy customers

In high‑throughput materials supply, a few hours of delay can cost a project or a customer. This operation relied on scattered spreadsheets and manual checks that could not keep up with demand.

- Manual bottlenecks: Customer records and quotations were spread across Excel files, turning every quote and update into hours of low‑value typing.

- Revenue leakage: Without automated credit checks, loads were dispatched to customers with high outstanding balances, increasing risk.

- Fragmented visibility: No single source of truth for order history meant teams struggled to answer basic questions during customer calls.

- Order fulfilment lag: The time between a customer request and actual dispatch was too long, putting construction timelines under pressure.

A unified customer lifecycle with SAZS Apps ERP

The SAZS Apps ERP Customer Management Module replaced disconnected tools with an end‑to‑end workflow: from first quote to final dispatch, everything lives in one system.

1. Automated quotation & order management

Sales teams now generate professional, branded quotations in seconds instead of manually building them in spreadsheets. Once approved, each quotation converts to a confirmed order instantly, notifying production teams at the crusher, quarry, RMC, or brick plant in real time.

2. Intelligent credit control & alerts

The ERP continuously monitors credit limits and ageing. If a customer exceeds the allowed limit or has long‑overdue invoices, new dispatches are automatically blocked until finance clears the account, protecting cash flow without manual policing.

3. Integrated weighbridge & dispatch sync

Customer orders are linked directly to automated weighbridge entries, ensuring every load is captured against the right order and rate. This removes manual data entry at the scale and closes gaps where errors or malpractice could occur.

4. Real-time order tracking

Customers in RMC and quarry segments now receive clear status from "Order Confirmed" through "In‑Transit" to "Delivered", giving both internal teams and clients live visibility on critical deliveries.

Peak efficiency and scalable growth

Within months of going live, the operation saw measurable gains in customer satisfaction, process speed, and financial discipline.